Need functional prototypes and fully assembled sheet metal components fast? Unlike traditional sheet metal shops, we have infinite capacity and easy-to-use online quoting system ensuring on-time shipment every time—whether you need a single part or 500 parts. At Work Technology, our sheet metal fabrication service is designed for rapid prototyping, end-use production, and assemblies.

Ready for a more cost- and time-efficient way to manufacture parts? Our high mold manufacturing knowledge and strong engineering team help you reduce design risks and limit overall production costs along every step of the product cycle. At Work technology, our injection molding and die-casting services are designed for both low-volume and mass production of end-use parts, production tooling for high-volume production, mass customization of product lines. Our plastic injection molding and die-casting processes produce custom prototypes and end-use production parts in 15 days or less.

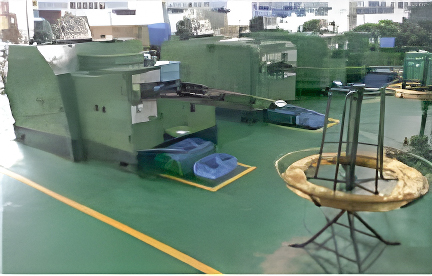

CNC milling refers to the process of using computer numerical control (CNC) machines to remove material from a workpiece, creating a custom-designed part or product. The number of axes in CNC milling machines determines the capabilities and complexity of the machining process.

Computer Numerical Control lathe & turning, is a machining tool that uses computerized controls to operate and manipulate cutting tools to shape materials such as metal, plastic, or wood. It plays a crucial role in modern manufacturing, offering efficiency, precision, and versatility in producing a wide range of components and parts. We have 3pcs of this equipment.  Precision  Automation  Versatility  Reduced Manual Labor

8618627301270

8618627301270 +86-186-2730-1270

+86-186-2730-1270